Theory of Polishing

We know that grinding, as performed by the mirror maker, is a fragmentation of the surface of the glass. The older theory of polishing was that it consisted of a sort of continuation of this process on a fine scale; that is. that the rouge particles, measurable in diameter in units of a wave length of light, were partially embedded in the pitch, the protruding edges having a planing action on the pitted surface of the glass. (This is what occurs when the surface of a pitch lap is charged with a fine grade of carborundum. A fairly good semi-polish can be obtained by-charging the lap with fine emery.) Later, the theory was advanced that a molecular flow occurred on the surface glass, induced by a high surface temperature resulting from friction. Substantiating this theory, there is evidence that minute particles of glass become detached from the surface, are adsorbed into the liquid, and either are redistributed or flow away.

In experiments conducted by Dr. E. D. Tillyer, of the American Optical Company, a lens surface polished with rouge was tested and found to contain no trace of iron, but after etching away the surface with hydrofluoric acid, a positive test for iron was obtained, indicating that glass had actually been deposited on top of minute particles of rouge. With further etching away of the lens surface, the actual marks of grinding were revealed, which certainly could not have been there if the polishing action were an abrading one.

In commercial work where close tolerances of figure need not be maintained, the polishing matrix, or rouge carrier, is usually of felt or even of paper. Spectacle lenses, simple magnifiers, and the like are thus polished. In the polishing of lenses, prisms, or mirrors, where high precision of figure is needed, a viscous sub stance such as pitch must be used. The surface of the pitch is charged with the polishing compound which acts upon the surface of the glass. The pitch can be made to conform with the optical surface, contacting it at every point and, in working, will flow so as to permit maintenance of contact with the ever-changing surface of the glass. On large work, channels are cut into the pitch, to facilitate its flow and reduce friction. These channels likewise serve as reservoirs for the liquid mixture of water and polishing agent.

In polishing with either cerium oxide or Barnesite, a higher frictional heat is generated than with rouge, and thereby a more rapid surface flow of glass is probably induced; at any rate, these agents are two or three times faster than rouge. The author can attest to numerous instances in which all trace of scratches that might ordinarily defy rouge was removed in upwards of an hour’s polishing with the aforementioned agents. Although there is little choice among the three products in the quality of polish obtained, Barnesite is probably superior in this respect. Some authorities are of the opinion that the fine figuring of optical surfaces cannot be successfully accomplished with the fast polishers, and adhere to the belief that the slower-working rouge should be used for this delicate task. But the drastic action of cerium or Barnesite can be materially subdued by applying it well diluted with water or by the addition of water only, since the charged lap will polish, with lessening effectiveness, indefinitely. So with a dilute mixture, and frequent interruptions of the polishing for long intervals of pressing, figuring can be expeditiously concluded with cerium oxide or Barnesite.

Polishing Procedure

Wax-coated laps sometimes undergo a brief breaking-in period during which the mirror may alternately slip and grab. Thickening the polishing mixture will help to alleviate this condition, although once the lap has been well charged with the polishing agent, it is desirable to work with as watery a mixture as possible.

The usual polishing stroke, which should be continued until all of the pits have been removed from the mirror, consists of a one-third diameter length used center over center, or it can be varied with a W stroke, in which the edges of the mirror are carried out to an overhang of about 1/2 on each side of the lap. The broken line in Fig. 30 indicates the path traversed by the center of the mirror in the performance of this stroke. When the lap is in good contact a perceptible drag will be felt, and some effort may be required in stroking. As to pressure, it is difficult to prescribe the exact amount in pounds to be used. A considerable amount may be needed in order to overcome the polishing drag, but it will be less than was used in grinding. Any tendency of the mirror to skid or jump should be resisted. The mirror at all times should pass back and forth across the lap with the two surfaces kept absolutely parallel, and to do this the worker, and not the lap, should control the mirror.

In order to handle the new technique better, your stance will have to be changed. In grinding, it was possible to stand up close to the work. In polishing, the feet should be spaced one back of the other, some little distance from the barrel. The pivotal action in executing the strokes should start at the feet or hips, not the shoulders or elbows, else there exists a tendency for the mirror to be rocked when the worker is reversing the direction of the stroke, causing a turning down of the edge.

Be sure in polishing that your fingers do not curl over the edge of the mirror to such an extent that they are in close proximity to the concave surface. So placed, they will warm and expand the edge there, which will polish off, and when the mirror has stabilized, its edge will be found to have been turned down. Also, when one’s fingers are hooked too far over the edge, an imperceptible tilt may be imparted to the mirror in drawing it back from the end of a stroke, causing its edge to plow into the pitch —- result, turned-down edge.

Work at the rate of about 20 to 40 strokes per minute, depending upon the drag of the lap. (Each stroke is the combined back-and-forth motion.) Frequent rotation of the mirror is not necessary, and never rotate it during a stroke, as the excessive action thus given to the edge zones will result in a depressed ring and a turned-down edge. A good procedure is to take six to eight strokes at one position, then shift about 45° to a new position where the strokes are repeated, then another 45° shift, and so on, giving the mirror a slight rotation at each second or third position only.

While the infrequent rotation is perfectly safe in general polishing, and is suggested to avoid excessive edge polishing, in figuring, the mirror should be rotated with each shift of position, as every precaution must then be taken to avoid any possible introduction of astigmatism. This fault results from failure to maintain a perfect surface of revolution. Working for too long a time in one position and taking too many strokes on the same diameter of the lap or of the mirror are obvious causes of producing different radii of curvature on different diameters of the mirror. This is one of the hazards to be contended with in attempting to figure the mirror with a fast-working polishing agent.

After 20 minutes of polishing, wipe the mirror clean with a soft cloth or absorbent tissue, wipe off any lint with the underside of the forearm, and observe your progress. The usual effect of the channeled lap on a spherical mirror is to polish most quickly at the center. A more even polishing action occurs with the use of the molded lap. Imperfect contact may cause zonal polishing. A hyperbolic mirror will polish most rapidly at the edge, in which case the stroke should be lengthened just enough to get the center of the mirror hitting the lap. This will also reduce the hyperboloid. If the polishing falls off abruptly before reaching the mirror’s edge, it indicates a flattened or turned-back edge from improper grinding. If, after another period of polishing, there is no indication of the lap hitting this edge (a remote possibility), a return to No. 220 carbo, grinding with the mirror on top and with short strokes, may be necessary.

How to Use the Foucault Device

At this stage you will naturally be curious about the figure on the mirror, and will want to experiment with Foucault’s lest. It is not essential that this test be conducted in total darkness, although delicate shadow contrasts are then more apparent. Placing the mirror in the testing rack, find the reflection of the lamp window on the piece of ground glass or sheet tin as was previously done in checking the focal length, and by adjusting the rack, bring the sharply focused image to a position like that in Fig. 19. Sit down with your eye about a foot in back of this point and, using a piece of ground glass, locate the position of sharpest focus. Bring the knife-edge up just tangent to this image and in the same plane with it, as nearly as possible, at the same time dispensing with the ground glass. Now reach out and slip the band containing the pinholes down so that the large pinhole is over the window.

If your head is still about a foot back of the knife-edge, the tiny illuminated pinhole image should be seen superimposed on the mirror. By changing the focus of your vision from the mirror’s distance to the usual reading distance, you will distinctly see the image of the pinhole suspended in space in line with the mirror and about a foot in front of your eye. The convergent rays from the mirror intersect in this point (see Fig. 21a), then diverge, and it is somewhere in this divergent cone that the eye is now centered. Shift the focus of vision back to the mirror, and now, by bringing your eye forward along the axis of the cone, more of the divergent rays are collected by it, and the pinhole image appears to expand on the mirror’s surface until, at a point where both the pupil of the eye and the divergent cone have the same diameter, the mirror appears fully and brilliantly illuminated. The distance of your eye from the knife-edge will then be about 21/2″ or more, depending on the size of the pupil. But it would sorely try your patience to attempt to test from this position, as your head can hardly be held immobile, and the slightest movement might cause you to lose sight of the image. So your eye should be advanced to within about 1″ of the knife-edge, where some latitude of motion will be enjoyed with less chance of losing sight of the reflection.

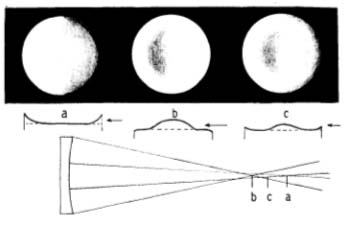

As zonal measurements are not going to be made at this stage, the knife-edge block need not bear against the guide cleat during these preliminary tests. The separation of the pinhole and knife-edge should not be great, however. Theory tells us that if they are at unequal distances from the mirror, an error is introduced in the correction formula for the paraboloid, and if they are widely separated laterally, astigmatism is introduced. But within a range of a few inches either way no measurable error can be observed. Now push the knife-edge across laterally until it cuts into the rays and causes a shadow to be cast on the mirror. Let us imagine that it is in the position shown in Fig. 31a. Here, it is inside the center of curvature, and the first rays to be cut off are those coming from the left edge of the mirror, so this part of it will darken first, the shadow advancing across the mirror from left to right, in the same direction as the knife-edge is moving. Now draw the knife-edge back about I/2″ toward the eye, to the position of Fig. 31b. Here, it is beyond the center of curvature, and the first rays to be intercepted come from the right-hand side of the mirror, so the shadow starts there and advances from right to left, in a direction opposite to that of the knife-edge movement.

|

We have now “bracketed the target,” as artillerymen say, and the center of curvature is somewhere between these two settings. It is finally found by repeated trials, and if the mirror is truly spherical it will darken evenly and instantly the moment the knife-edge has cut completely across the pinhole image, and no direction of shadow approach can be detected. Even with an unduly large pinhole, this condition would still be true.

A spherical surface will hardly be found at this stage, however, and instead of all of the reflected rays intersecting at c, there will probably be a scattering of intersecting zonal rays along a short section of the axis of the cone, as in Figs. 21b and 32, or possibly as in Fig. 39. In these cases, as the knife-edge is cut in, some parts of the mirror will remain illuminated while other parts are in shadow. With a very large pinhole, slight zonal discrepancies, distinguishable only by a faint contrast in shading, might not be apparent in the broad transition from light to shadow, and for this reason a large pinhole is less sensitive than a small one.

It will be difficult to slow down the lateral motion of the knife-edge sufficiently at the moment of its juncture with the axis of the reflected cone of light, so if its motion is arrested as it is about to cut into the rays and gentle downward pressure is applied with the fingers at the right side of the baseboard (Fig. 19), you can probably achieve nice control. If pressing on the baseboard is too lively, apply the pressure to the top of the bench or stand. Always press at the same spot.

In interpreting the shadows which are seen on the mirror, the observer may imagine himself to be in an observation balloon, viewing a small section of the earth’s surface (the mirror), which may be a plain, a hill, a crater, or any combination of these contours, as it is being illuminated by the grazing rays of the rising or setting sun (located somewhere to the right of the mirror). In this way a sphere, evenly gray in appearance, would resemble the flat surface of a plain. Even without any exercise of imagination, under the shadow test a sphere does look as flat as the proverbial pancake. See Fig. 31c, showing knife-edge setting, shadowgraph, and apparent cross-section of a spherical surface.

An oblate spheroid, with its center zone of longer radius, is shown in Fig. 32. The figure is revealed not only by the knife-edge settings, but by the apparent hill that may be seen on the mirror. The slope facing the imaginary sun is illuminated by it, and the opposite slope is in shadow. (The imaginary hill must not, of course, be presumed to cast a shadow, as the source of illumination is only imagined to be at the right.) The surrounding plain is gray, and since the knife-edge is at the center of curvature of that zone, it has the appearance of flatness (Fig. 32, b and c).

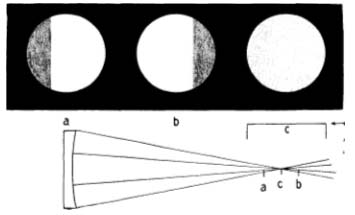

It is found that different knife-edge settings will produce different shadow appearances and different apparent cross sections of the same mirror. For example, Fig. 32 shows the shadows and apparent cross sections of an oblate spheroid when the knife-edge is placed at the center of curvature of the center zone a, edge zone b, and an intermediate zone c. It should be noted that, in the case of the oblate spheroid, apparent elevations represent glass that lies above that reference sphere (shown by the dotted lines) at the center of which the knife-edge happens to be at the moment. By removing the elevations from any of these three figures, a sphere would be obtained, but not, of course, the same sphere in each case. Fig. 33 shows how the shadows appear on a hyperboloidal mirror, wherein the center zone is of a shorter radius than the edge zone. By means of a diagram, the student should show the knife-edge setting that would produce these shadows.

|

|

Further Polishing

One may well be a little slow in comprehending all this, but no matter; get the mirror back on the lap and continue the polishing. You can dwell on the whys and wherefores of shapes and shadows while walking around the barrel. The immediate concern is to polish out the mirror completely, which may take from two to six hours, depending on the thoroughness of the fine grinding, and on the polishing agent used. The polishing mixture should be thinned so that on looking through the overhanging part of the mirror at the end of a stroke, only a faint coloration is visible. Renew the charge only as often as is necessary to keep a supply of liquid in the channels. With the molded lap, a single watery application will last almost indefinitely.

After working for a half-hour, give the lap a rest. Center the mirror on it, lay the board on top, and place a weight of about 20 pounds on top of that; then allow to press for about 10 minutes. This operation is known as cold-pressing, and should be indulged in frequently. If polishing spells are too long, the lap may soften and cause trouble. On account of the friction drag, the soft lap tends to follow the mirror as it passes back and forth, causing an excessive deepening of the renter. This results in an apparent crater or hole there, or possibly a hyperboloidal figure. A turned-down edge may also result from plowing into the soft pitch. Following numerous periods of polishing and pressing, the pitch may sink a perceptible amount, flowing into the channels and spreading out so that the lap has a larger diameter than the mirror. Therefore an occasional trimming is in order. The channeled lap may be kept as much as 1/16″ less in diameter than the mirror as a safeguard against turning the edge. Don’t trim it too small or a turned-up edge may be the result. The harder pitch of the molded lap should stand up long enough to see the mirror through to its completion.

When replacing the mirror on the lap after it has been on the testing stand, you may observe that the polishing drag is not as even as before. This is because the central and more heated area of the lap has sunk more than has the area around the edge, and the mirror will then be riding on a high outer ring of pitch. If polishing were resumed immediately, a turned-down edge and a central hill would result from the mirror being plowed into this ring of pitch. So it is essential, after the mirror has been off the lap for more than a few seconds, that a sufficient amount of time to restore contact (15 minutes or more) be allowed for cold-pressing.

Examining for Pits

Pits are apparent in the early stages of polishing by the grayish appearance of the surface, especially at the edges. This grayness is the diffused reflection from the myriads of tiny pits left by the emery. As polishing progresses it disappears, until the surface has the appearance of being fully polished. But do not be deceived by this first impression. On the silvered or aluminized mirror, the all-but-invisible pits that may still be present would stand out in disastrous prominence. (Some expect the silver or aluminum coating to fill up tiny voids, such as pits and scratches, but as it is only a fraction of a wave length of light in thickness, the coating merely “lines” them and renders them more visible.) With a reading glass, focus the image of the sun or any bright light on the mirror’s surface. A small patch of wet paper stuck to the surface will guide the lens to the position of sharp focus. Where any pits are present, the “burning spot” will show up clearly. It can barely be seen on a fully polished surface. Compare its appearance at the center, which area will have the best polish, with that near the edge of the mirror.

Or hold the mirror so that the reflection of an overhead light is seen on its surface, near the edge. Draw it up close to the eye, keeping the reflection in view, and place a magnifier before the eye. Scan the surface of the mirror at the edge in the vicinity of the light reflection, and the pits can be seen, if there are any, looking like a. very fine powdering of dust particles. If you have difficulty in seeing the pits this way, hold the mirror with a frosted lamp back of it and examine the surface with the aid of the magnifier. Any pits should be visible against the luminous background. Polishing should continue until they are no longer visible. If necessary, the stroke should be shortened to facilitate polishing of the edge.

Correcting

Under the Foucault test at the completion of polishing, the figure on the mirror will probably be some variation of the oblate spheroid, perhaps with a turned-down edge. This is because, under the work of fast polishing, the lap has sunk more at the center, and the edge of the mirror has been riding into a higher level of pitch. Sufficient cold-pressing, as discussed above, will have helped to alleviate this condition. If the mirror is hyperboloidal at this stage, either the lap is too soft or too long a stroke was used. Regardless of the shape of the mirror, it should be brought to a spherical figure preliminary to parabolizing.

The first step in the correcting process is to check the condition of the lap. If it appears to be working well and is responding satisfactorily, only a little trimming is in order. If it has spread out around the edges or closed in on the channels, trim it back neatly and carefully with a razor blade. If the surface appears pretty well glazed, scrape off the wax coating with the flat edge of the blade and rewax. If you are using the molded type of lap, leave it alone if it is satisfactory, but if the facets have sunk down or have run together (an indication of too-soft pitch) chip it off with an old chisel, wipe the surface of the tool clean with turpentine, and make a new lap. A dulled and unresponsive lap can often be revitalized by warming its surface over a stove until the wax shows signs of melting, then recharging it and pressing it into contact with the mirror.

Frequently some roughness, zonal rings, or even a pattern of the lap may be seen on the mirror under the knife-edge test. A drastic polishing action or the use of short strokes is the cause of this. Thinning down the polishing mixture and a slight lengthening of the stroke, together with the blending effect of zigzagging (Fig. 30) should smooth up the surface.

Turned-down Edge

This is a narrow zone around the mirror, usually about 1/8″ or less in width, but sometimes as much as ½in which the radius of curvature is rapidly lengthening. On the apparent surface of the mirror, it is somewhat like the run-down heel of a shoe. If left uncorrected in the telescope, a turned-down edge will pitch its rays out beyond the focus of the rest of the mirror, some of them causing an image blur and others passing into the eyepiece and fogging up the field of view.

Under the knife-edge test, there will always be a diffraction ring around the right-hand edge of the mirror, very brilliant if the edge is badly turned. In that case the left-hand edge of the mirror will appear to be soft and dark. If the mirror’s edge is perfect, there will be a fine, continuous hairline of light entirely surrounding it, of nearly equal brightness on both sides. The ring on the right should not persist beyond the point where the diffraction disappears from a straightedge suspended across the face of the mirror.

To correct turned-down edge, use short strokes if the edge is badly turned, otherwise the one-third stroke should bring out the diffraction ring, provided proper attention is paid to maintaining contact. Work for five minutes and cold-press for five minutes. After three or four such spells, try the knife-edge test, and if the diffraction ring is making an appearance, continue with that treatment; if not, use a shorter stroke. An excellent aid to securing contact in cold-pressing with the channeled lap (it is’ not necessary for a molded lap) is the use of a piece of onion sacking. An empty onion bag can be bought at a vegetable store for a few cents. Spread a piece of the material over the lap, lay the mirror on top, and then apply the weights. This breaks up the surface of the lap into numerous small facets which, under polishing, more easily conform to the changing surface of the mirror.

Turned-up Edge

This is a narrow edge zone of shortened radius of curvature. It is conspicuous by a thin strip of shadow just inside the diffraction ring around the right-hand edge. The corresponding zone on the left edge is very bright, and if the zone is very narrow, this may be mistaken for the normal diffraction ring of a perfect edge. Turned-up edge seldom occurs in more than mild form, and usually works out under the long and overhang strokes used to correct the oblate spheroid, or to parabolize. It may result from the short strokes used to correct a turned-down edge, or from a lap that has too small a diameter. If it is stubborn, polish upside down for a few minutes, with short strokes. This will probably cause the edge to turn down, and some correction will be necessary to restore the diffraction ring. When satisfied with the edge, go after the rest of the figure.

Correcting the Oblate Spheroid

In the discussion of the oblate spheroid, it was stated that any of the three apparent shapes in Fig. 32 could be converted into a sphere. It is obvious that it would be difficult to select a stroke that would correct a. The apparent shape at b can be handled by the use of a long stroke, but there is quite an amount of glass in that central hill, and excessive long-stroking will turn down the edge. There is less glass in the central hill in c, and enough in its edge zones to offset the effects of the long strokes, so that is the knife-edge setting that ought to be used for correction.

Hot-press for contact. Use a one-half diameter W stroke, extending the overhang on each side to the boundaries of the hill. Polish for five minutes and press for 10, and test after two such spells. If the hill is being planed down evenly, continue the same stroke, first restoring contact by hot-pressing if necessary. If a crater or hole is showing up at the center of the hill, reduce the stroke length. If progress seems too slow, lengthen the stroke, or slightly increase the overhang on one side. Watch out for a lengthening radius of the edge zones, an indication that the stroke is too long. Hard laps will permit a wider range of strokes than soft ones. If good contact is being maintained through long periods of cold-pressing, the edge will not be impaired, and the blending overhang stroke will be ironing out any zonal rings or roughness that may have been caused by the short strokes used in edge correction. With the harder pitch of the molded lap, the periods of corrective polishing can be extended to 10 or 15 minutes. Use of a rapid stroke will often bring a hill down fast, but look out for turning the edge. Finally, to wipe out any zonal irregularities remaining from the oblate figure, return to the one-third W stroke (Fig. 30), cold-pressing frequently for long intervals; or hot-press if necessary. Eventually the mirror will be whipped into a spherical figure, and on the Foucault stand it will appear flat and velvety smooth.

Correcting the Hyperboloid

The hyperboloid is usually the result of overshooting the paraboloid, or too zealous work in reducing the oblate spheroid. In it, the radius of curvature of the center zone is shorter than that of the edge zone; this is likewise true, of course, of the ellipsoid and the paraboloid, but with the hyperboloid the distance between the intersections of these radii with the axis is greatest. On the Foucault stand, the shadow boundaries on all three figures will be alike, but the shadow depths will differ (see Fig. 33), the shadows darkening at a rapid rate as the distance between the centers of curvature (ba, Fig. 39) increases. The treatment to be applied here is similar to that described for correcting the hyperbolic figure that was had from long-stroke grinding (Fig. 23). There, it will be recalled, the edge zones had to be worn back by grinding with short strokes. Now, the knife-edge should be set at the center of curvature of the edge zone, and the figure seen (Fig. 39a is similar) is taken for correction. The edge glass must be planed down to the level of the depth at the center, and this is done with a short stroke. With this stroke, however, the distribution of the polishing cannot be so controlled as to return the figure to a sphere. Instead, an oblate spheroid is usually the outcome, and that figure can in turn be dealt with as already described. Occasionally, where the overcorrection is not great, and especially with the molded lap, a knife-edge setting similar to Fig. 39c can be chosen, and the crests, or 70-per-cent zone (explained in the next chapter), planed down smoothly until the overcorrection is brought within the allowable tolerance.

It is quite all right to leave the mirror on the lap overnight if desired, but weights may be dispensed with. Wrap a wet cloth around the disks to prevent evaporation, and the next day you are off to a flying start with perfect contact.