Herschel’s Contributions

Despite the attendant difficulties, a number of very large specula were made, some of the best by William Herschel. Born in Hanover, Germany, Herschel settled in England in 1757, where he became interested in astronomy and later (1776) turned his attention to telescopes. Working entirely by hand, at first as an amateur, he practiced and developed his technique on a great number of Newtonian telescopes, and learned how to figure the mirrors far better than had any of his predecessors. He performed the polishing in the conventional manner, with the mirror on top, and used a sweeping, circular stroke for parabolizing.

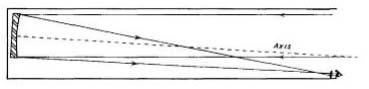

Later, Herschel applied himself to the design now referred to as the Herschelian type, which had been proposed by LeMaire, a French scientist, in 1728. In this design (Fig. 12), the mirror is tilted so that the image is thrown to one side of the open end of the tube, where it can be examined in comfort, with the observer’s back to the object, and without the introduction of a second reflection. This latter feature was of tremendous importance in the days of speculum, when 40 per cent of the light was absorbed in undergoing a single reflection. Of less importance, but nonetheless gainful, was the elimination of the harmful diffraction effects from the secondary mirror. But unless a suitably high focal ratio was chosen, astigmatic images resulted from the inclination of the mirror. And this introduced another problem; the lengthening of the tube meant placing the observer at an awkward height.

|

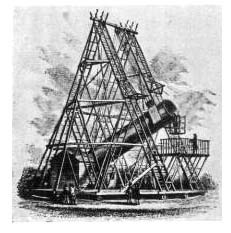

In 1789, Herschel completed his largest reflector, of the tilted-mirror type, which was installed at Slough, near Windsor. The speculum was four feet in diameter, with a focal length of 40 feet. It was about 3½” thick, and weighed about 2,100 pounds. An elaborate and ingenious trestlework was built to carry the observer. (See Fig. 13.)

This great mirror was exceeded with the completion in 1845 of the largest of all specula, one six feet in diameter and 54 feet in focal length, by the Irish astronomer, Lord Rosse. The metal disk was nearly 6″ thick, and weighed about 8,380 pounds when cast. Rosse’s gigantic instrument was mounted at Parsonstown, Ireland.

As representative of the prices Herschel charged for his reflectors, a Newtonian model of 6½-inch diameter and seven feet focal length sold for 100 guineas (30 guineas for the optical parts). Another 8.8-inch Newtonian, 10-foot focus, cost 200 to 300 guineas. Herschel advised buying two mirrors for this latter instrument (which probably accounts for the variable price) so that one could be used while the other was being repolished!

His talents were not confined to the making of fine specula; he also made his own eyepieces, some of which were truly remarkable. His frequent references to the use of magnifications of some 7,000 on his 6½-inch reflector occasioned some speculation and controversy among the English astronomers, but his claim appears to have been justified by the discovery, comparatively recently, of some very tiny eyepieces made by Herschel. Among his effects at Slough, W. H. Steavenson found several of these eyepieces, varying in focal length from about 1/16″ downward. The smallest of these was examined in a microfocometer, and found to have a focal length of 0.011″. It was bi-convex, about 1/45″ in diameter, and 1/90″ in thickness. It was tried out on a 6-inch refractor, and performed as creditably as its power would permit, but its field in that instrument was only about 20 seconds of arc in diameter. If Herschel actually used this eye-piece on his 85.2″ focal length reflector, it would have given a magnification of 7,668.

|

|

The Achromatic Refractor

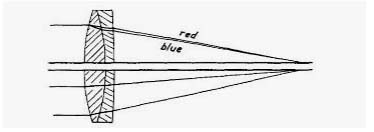

In 1733, the achromatic lens (Fig. 14) was invented by Chester Moore Hall, an English barrister. This was accomplished by combining a convex crown and a concave flint lens in such a way that their focal lengths were inversely proportional to their dispersions. Although a number of telescopes were made according to Hall’s instructions, the benefits of the achromatic lens do not appear to have been made available to the public until John Dollond invented it independently in 1758, and patented it. Dollond’s efforts led to a demand for clearer glasses of more varied densities and of less equal dispersions, needed to improve achromatism, and chemists pursued experiments in learning how to control the refractive indices of melts, and in the pouring of large disks of limpid, homogeneous glass. Altogether, excellent progress began to be made, and by 1800 achromatic objectives 6″ in diameter were being turned out. Some of the best glass had been manufactured by Guinand, a Swiss who worked with Fraunhofer from 1805 to 1814. Fraunhofer produced a number of splendid achromats up to 9″ in diameter.

|

Dollond was making refractors (spyglasses) with single-lens objectives as early as 1742, his price for a 2-foot telescope then being 7s 6d. In comparison, in 1762 he sold a 2-foot telescope with a two-lens objective (achromat) for 2 guineas. The lens diameters in each case were just under 2″.

In 1783, with a view to combining the benefits of the wide field of Huygens’ eyepiece with a means of making micrometric measurements of an image in the focal plane, Jesse Ramsden, an English optician, designed the compound eyepiece shown in Fig. 68. ft can be seen (more clearly, perhaps, from Fig. 65) that a measuring device, such as adjustable parallel wires, set in the focal plane would be magnified along with the image. Measurement of an image in the focal plane was by no means a new idea; probably this had been first accomplished by Gascoigne, an Englishman, about 1638.

With the advent of the achromatic lens, the erecting or terrestrial eyepiece assumed considerable importance. This type of eyepiece was first suggested and used by Kepler, and improved in design about 1645 by Antonios Maria v. Schyrle, a Capuchin monk better known as Rheita. It is mentioned here because it spelled the rise of the refractor and the decline of the Gregorian for terrestrial use. As the terrestrial eyepiece has no significance in astronomical instruments, it will not be further discussed. Information on it can be found in any treatise on optical instruments.

In the early part of the 1.9th century, small achromatic refractors were being manufactured by several concerns. Prices, for apertures of 2″ to 3l/2″, ranged from 10£ to 50£. This included a pillar and claw stand, and in most cases, a rack work for focusing. With the larger sizes, three eyepieces of different powers were also included. A 5½-inch refractor by Dollond sold for 350 guineas. The lens alone could be purchased for 200 guineas. For those not having the means to buy achromats, telescopes with single-lens objectives continued to be made. Enterprising opticians were also offering lens sets that could be assembled into simple refractors.

The Modern Era

The method of chemically depositing silver on glass discovered about 1840 by Justus von Liebig, of Nuremberg, was successfully applied to a small glass telescope mirror in 1856 by Karl Steinheil, a German physicist, and independently in the following year by Jean Foucault, the famous French physicist.

Then, in 1858, Foucault announced the development of his amazingly delicate and simple test for a concave reflecting surface, using an illuminated pinhole and a straightedge placed in the vicinity of the center of curvature of the mirror. The pinhole and straightedge were the outgrowth of earlier experiments in which simultaneous microscopic comparison was made of a pin point, likewise placed at the center of curvature of a mirror, and itsreflected image, which was caused to fall alongside.

The last speculum of note to be constructed was one four feet in diameter, made by Grubb in 1870 for the Melbourne Observatory. Silver-on-glass mirrors replaced the more expensive and difficult-to-work speculum. Silver was far more efficient as a reflector, for a freshly deposited coat reflected somewhat better than 90 per cent of the light in the visible spectrum. It tarnished, but not nearly so quickly as speculum, and it could be removed by chemical means and a new coating applied without upsetting the figure of the glass surface.

Now, accompanied by Foucault’s method of testing, reflecting telescope making by amateurs began to spread, slowly at first, throughout the civilized world. Books and articles on astronomy frequently contained instructions on the subject. Almost any thick disk of glass stood a fair chance of terminating its career at the bottom of a telescope tube. Porthole lights were especially preferred on account of their ready-made size.

The secret of the achromat was still the guarded possession of the professional optician, but simple lenses, in sets, and achromats as well continued to be offered on the market. Prices taken from catalogues of the year 1878 were, for single lenses, from two to six dollars for diameters of 1½” to 3″. The higher-priced assortment included a “genuine Huygens eyepiece mounted in brass.” Achromatic lenses, diameter 2″, focal length 30″, sold for $4.50, and 4-inch achromatic lenses of 60″ focal length, with “extra fine finish,” were priced at 75 dollars.

Almost the only obstacle now in the path of the reflector was the problem of casting and annealing larger glass blanks. These first glass mirrors, and even those of quite recent years, were of ordinary1 plate. The chief source of trouble was the high coefficient of expansion, with the resulting injurious effect on the figure caused by temperature changes. (Similar difficulties had been encountered with speculum metal, which had more than double the coefficient of expansion of plate glass, but the effects were no more pronounced due to the much thinner disks that were used. The thinner disks, however, were quite sensitive to flexure.)

Extensive experiment was undertaken in the United States, following the first World War, toward the development of a low-expansion glass. This resulted in a product called pyrex, first used for baking dishes. As is well known, pyrex was used in the casting of the 200-inch mirror blank, at Corning, N. Y., in 1934. Its coefficient of expansion is only one third that of plate glass, materially reducing deformation due to temperature changes. It is harder than plate glass and more difficult to grind, but it is also more resistant to scratches.

Following the successful pouring of the 200-inch disk, a clamor for this new glass went up from amateurs everywhere. The Corning Glass Company responded by providing suitably annealed disks in various sizes. It is fortunate that the homogeneity of the glass does not have to be taken into account. The melting point of pyrex is high, about 2,900° F., and even then it flows like cold molasses. As a consequence, folds, striae, bubbles and stones, in no way impairing its qualities as a foundation for a mirror, are to be found in almost any blank.

Fused quartz has been experimented with also; in fact, it was first thought to make the 200-inch of this substance. A number of mirrors and optical flats, of various sizes, have already been made of it. It has one sixth the coefficient of expansion of pyrex, and is absolutely impervious to the most extreme climatic temperature changes. The cost of manufacture, however, will keep it out of the hands of most amateurs for the present.

At the close of the 19th century, experiments began on the deposition of metal films on glass by an evaporation process in high vacuum. These have resulted in the replacement of the silver mirror coating by a more durable one of aluminum. Although a number of metallic elements have been evaporated, some of them having a higher reflective index than aluminum for certain wave lengths, the efficiency of aluminum over the entire spectral range is higher than that of any other metal. It is but slightly less efficient in the visible spectrum than a fresh silver coat, with a reflective index of about 88 per cent, but it retains this reflective quality almost indefinitely. Its absorption in the ultraviolet is considerably less than that of silver, and so it is decidedly superior for photographic purposes. The first mirror to be coated by the evaporation process was the 15-inch of the Lowell Observatory. This was done in 1931 by Cornell University researchers, using chromium.

The largest refractor in the world today is the 40-inch telescope at Yerkes Observatory, Williams Bay, Wis. The lens, which has a focal length of 63.5 feet, was completed in 1895 by Alvan Clark. This is probably the ultimate in size for a refractor, because of flexures imposed by the weight of larger lenses, and also because of a serious light loss by absorption in the thick lenses.

The largest plate-glass mirror in use is the 100-inch, ratio f/5.1, at Mount Wilson Observatory. The glass blank was cast at the St. Gobain Glass Works in France and shipped to Pasadena, where it was made into a mirror by George Ritchey.

The 200-inch reflector, f/3.3, of the observatory on Mount Palomar, is by all standards the greatest of telescopes, a far cry from Newton’s first reflector, 1 1/3″ in diameter.

Reflector or Refractor?

In the past there has been considerable discussion on the relative merits of reflector and refractor. From the standpoint of professional astronomers, there is no serious competition between them, as each type supplements the other in a well-rounded observing program. An amateur who plans to build his own instrument and to use it for general observing has other factors to take into consideration. Let us first look at some of the optical characteristics of reflectors and refractors.

Very early in the 19th century, when advocates of the speculum mirror began to feel the challenge of the refractor, Dr. Nevil Maskelyne, English Astronomer Royal, ventured the opinion “that the aperture of a common reflecting telescope, in order to show objects as bright as the achromat, must be to that of an achromatic telescope as 8 to 5.” The relative inefficiency of the reflector of that day was due to the fact that, even under most favorable circumstances, barely 40 per cent of the original light escaped absorption by the metal mirrors, the greatest losses occurring in the short and medium wave lengths. Even silver-on-glass mirrors are subject to considerable deterioration, especially under certain conditions of the atmosphere.

The reflectivity of aluminum, however, is more-or-less constant, and from a standpoint of image brightness, it placed the reflector on a more equal footing with the refractor. In fact, until the quite recent development of anti-reflection lens coatings, an aluminized mirror has had the same efficiency, in light-transmitting qualities, as an air-spaced achromatic objective lens of equal aperture.

Coming down to figures — due to reflection there occurs in an untreated lens a light loss of slightly more than four per cent at each of its surfaces.

With these reflection losses to be accounted for, plus an absorption loss in the substance of the glass (amounting to about two per cent for lenses of moderate size), it is evident that about 82 per cent of the original light is transmitted. In the reflector, after first deducting that area of the mirror’s surface obscured by the diagonal, an equal percentage of the original light is found to be transmitted. Of course, this transmitted light is subject to another reflection by the diagonal, but the refractor will probably employ a star diagonal, the function of which is similar to that of the diagonal or prism of the Newtonian, so an equivalent loss may occur there. Therefore, with either instrument, the same amount of light reaches the eyepiece.

It was discovered, however, in the latter part of the last century, that some lenses which had been tarnished by the elements transmitted more light than ones that were newly polished; it was found that this resulted from lessened reflections at the tarnished surfaces. Various processes of producing an artificial tarnish were attempted. At present, in the most satisfactory method, metallic salts (such as magnesium fluoride) are evaporated in a high vacuum onto the glass. Ideally, the refractive index of an anti-reflection fluoride coating should vary from that of glass at the glass-fluoride surface to that of air at the fluoride-air surface, in which case no reflection would occur. Practically, the index of the coating should be equal to the square root of the index of the glass, and its thickness equal to a quarter of a wave length of yellow-green light. Only the light at opposite ends of the visible spectrum is then reflected, amounting in general to less than one per cent of that of the whole, and is detected by the purplish color given to the reflection.

The different fluorides vary in hardness, magnesium fluoride being perhaps the most durable anti-reflection coating for exposed surfaces. The cost of application of the coatings is high, but thus improved, the refractor again moves up ahead of the mirror in light-transmitting qualities, a lens of about 51/2-inch aperture being the equal, in this respect, of a 6-inch aluminized mirror.

In the matter of resolving power, the 6-inch mirror will excel the 5½-inch lens, although diffraction caused by the obstructive secondary mirror and supporting vanes of the reflector has a more-or-less deleterious effect on the image. The open ends of the reflector tube admit air currents which may further contribute to the impairment of image formation. Thus it may not be possible to realize the full theoretical limit of resolution of the mirror.

A considerable amount of correction of off-axis aberrations is effected in a suitably designed doublet lens; this cannot be accomplished in a mirror alone. If the instrument is confined to visual use, however, these aberrations

do not seriously handicap a telescope, as the observer naturally brings the object under observation to the center of the field, where definition should be limited only by diffraction.

On the other hand, the mirror is perfectly achromatic, while the doublet cannot be entirely freed of color. In order to reduce the residual color to a tolerable minimum, the ordinary refractor is usually designed in ratios from about f/15 to f/20, although, in the smaller diameters, it is sometimes made as low as f/10. The more versatile reflector may range from f/3 to about f/12, limited in the higher ratios by the accessibility of the eyepiece. In the short instruments, provision can be made for amplifying the ratio, when desired, permitting of observation at either the Newtonian or Cassegrainian focus.

Observing comfort with the 6-inch Newtonian demands that it be confined to a ratio of f/10 or less, in which sizes it can be made portable; in this respect the longer tube of a 5½-inch refractor may present a problem. Again, from the standpoint of comfort, the Newtonian has advantages over the refractor. The latter instrument, although equipped with a star diagonal, often places the observer in cramped positions.

Probability of success on his first attempt, cost, and upkeep are three important factors to be weighed by the amateur. On his first venture, if he follows the instructions in this book with patience and care, he may expect to produce a reasonably good mirror; if it differs materially from the pre-ordained focal length, it does not matter. On the other hand, were he to attempt to make a refractor first, his lens would very possibly prove a total and expensive failure (good glass for a 5½-inch achromatic lens costs about 40 dollars). Any deviation from the prescribed radii of any of the four lens surfaces, by more than a very small per cent, increases seriously the amount of residual color.

As for cost, the excellent reflector shown in the frontispiece was constructed at a total outlay of only 30 dollars, whereas a refractor of somewhat equal capabilities would probably cost not less than 150 dollars.

Upkeep is slight for any telescope, and least for a refractor. The reflective aluminum coating of the mirrors of a reflector is subject to deterioration from dust and the elements admitted by the open tube, but given the same protection when not in use that is accorded a refractor, at least two years of service should be realized before the aluminizing job need be repeated.

From the standpoint of an introduction to the optician’s trade, the experience of thousands of amateurs has shown that one’s teeth should first be cut on at least one good mirror. Then, if a refractor is contemplated, additional experience can be gained by making the optical flat that is so essential in the testing and figuring of the objective lens. (See Appendix B.)

What Size Reflector?

As already mentioned, telescopes are usually designed to perform particular kinds of work. Some are meant to be used chiefly for photography. In general, for visual work, low-ratio telescopes with their wide fields are useful for comet seeking, variable star work, and the like. The higher ratios are used in planetary study, double star observations, and in other fields where high powers and fine definition are required. Some of these instruments are portable, and others must be mounted on a solid pier. The amateur, however, usually will have formulated no particular plan of observation, except a desire to explore the heavens, and to see with his own eyes some of its wonders.

From the experience gained by amateur telescope makers, it has been found that the most practical and popular instrument for amateur use is the 6-inch f/8 Newtonian reflector. Its concave mirror is 6″ in diameter and its focal length 48″. The delicate task of parabolizing the mirror, while not easy, is not beyond the ability of a careful worker. The 4-foot focal length makes for comfortable observing, and with a low-power eyepiece, the field of view is a trifle over one degree in diameter — more than twice that of the full moon. The magnifications that may be employed permit of a modest size of mounting, which can be made portable. Such a telescope should reveal stars of magnitude 12.8, as compared with the 6th-magnitude limit of the unaided eye, and the 9th-magnitude limit of the average small binocular. Theoretically, the mirror is capable of resolving double stars having a separation of % of a second of arc, but as magnifications exceeding about 30 per inch of aperture can seldom be used, it may not be expected to perform up to this limit. This telescope will show the divisions in Saturn’s rings; surface markings on the moon little more than a mile across should also be visible.

The purchase price of such an instrument of professional make is necessarily high, and many an amateur feels compelled to do without it. But if he is possessed of some ingenuity and craftsmanship, and is willing to devote a few hours a week to the task, he can in a relatively short time build the telescope in its entirety, for a small fraction of that price. Of course, many amateurs feel that their mirrors are inferior to the professionals’, but this is not necessarily true. It has been frequently demonstrated that mirrors of professional make will seldom stand up to a test, because it is impossible for the professional optician to spend sufficient time on the mirror without losing money, whereas the amateur can, if he will, devote all the time and care necessary to produce a mirror of admirable figure.

In the following account, the amateur astronomer will be introduced to the optician’s art of grinding and polishing spherical surfaces on glass. He will learn how to alter the concave spherical surface to a paraboloid, an achievement that baffled the world’s opticians for 50 years, from Newton to Hadley. He will learn how to make and test an optically plane surface. He will find out why and how to make an equatorial mounting. He will take pride in his telescope, and derive profound pleasure from using it, because it will be a good one, and because he made it himself.

|

|